Loading day & date...

Loading time...

PSA Nitrogen Gas Plant

* Purity: 95% to 99.999%

* Capacity: 5 to 1500 Nm³/hr

* Design: Skid-Mounted / Modular

* Applications: Industrial, Medical & Food – incl.

- Packaging, Electronics, Metal Processing, Pharma, Chemicals

* Features: PLC Control, Auto Operation, Energy Efficient, Low

- Maintenance, Optional Purity & Dew Point Analyzer

* Support: On-Site Installation, AMC / CMC

* Support Hours: 24/7

PSA Oxygen Gas Plant

* PSA Oxygen Gas Plant Technology

* Purity: – 90% to 95% Oxygen

* Capacity: – 5 to 1000 Nm³/hr

* Skid Mounted / Modular Design

* Applications: – Medical, Industrial,

- Pharmaceutical, Wastewater Treatment

* Features: – Fully Automatic Operation, Touch

- Screen PLC Control, Low Power Consumption

* On-Site Installation & AMC / CMC Support Available

* Support Hours: 24/7

Ammonia Cracker

Purity: – 75% Hydrogen (H₂) + 25% Nitrogen (N₂)

Capacity: – 1 to 1000 Nm³/hr Skid Mounted

Applications: – Heat Treatment, Annealing, Sintering, Brazing, and other Industrial Uses

Features: – High Efficiency Catalytic Reactor, Automatic Temperature Control

On-Site Installation & AMC/CMC Support Available 24/7

Bio Gas Plant

* Methane Purity: 90% to 98% (Bio-CNG Grade)

* Capacity: 5 to 10,000 Nm³/day (Customizable as per Requirement)

* Design Type: Modular / Skid Mounted / Fixed Dome

* Feedstock Options: Food Waste, Agricultural Residue, Animal Waste, Sewage Sludge, Industrial Organic Waste

* Applications: Power Generation, Industrial Heating, Cooking Gas, Vehicle Fuel (Bio-CNG), Waste-to-Energy Projects

* Features: Eco-Friendly Operation, Odor Control System, High Gas Yield Efficiency, Easy Maintenance, PLC-Based Automation

* Additional Support: On-Site Installation, Commissioning, AMC / CMC Available

* Support Hours: 24/7 Technical & Service Assistance

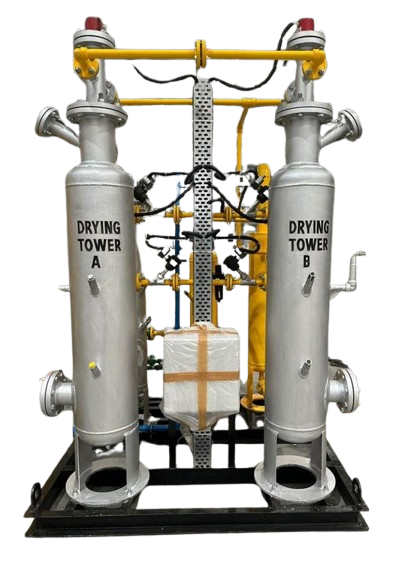

Desiccant Air Dryer

* Technology: Twin-Tower / Heatless / Heated / Blower Reactivated Systems

* Dew Point: Up to –80°C for Ultra-Dry Air

* Capacity Range: 5 CFM to 5000 CFM (Custom Design Available)

* Design Type: Skid Mounted / Modular Compact Design

* Applications: Oxygen & Nitrogen Gas Plants, Instrument Air Systems, Chemical & Pharma Industries, Food Processing, PET Blowing, and Paint Booths

* Features: Energy-Efficient Operation, High-Quality Desiccant Media, Low Pressure Drop, Fully Automatic Cycle, Long Service Life

* Optional Accessories: Pre & After Filters, Moisture Separator, Auto Drain Valve, Dew Point Indicator

* Additional Support: On-Site Installation, Commissioning, AMC / CMC Service Available

* Support Hours: 24/7 Technical Assistance & Maintenance Support

MS, DE-OXO, and CU DX-OXO Modules for PSA Nitrogen Gas Plants –

Delivering Nitrogen Purity from 99.5% up to 99.9999%

PSA and VPSA Oxygen Gas Plants –

Supplying Oxygen with 93% ±3% Purity for Medical and Industrial Use

your trusted partner in advanced gas generation and purification systems. We specialize in PSA/VPSA Oxygen Plants, Nitrogen Gas Plants, Biogas Systems, Ammonia Crackers, High Pressure Boosters, and complete servicing of existing gas installations. Backed by technical expertise and industry experience, we deliver efficient, reliable, and cost-effective gas solutions for industrial and medical applications across India.

AmsaAir Engineering, based in Greater Noida since 2017, specializes in PSA/VPSA Oxygen Gas Plants for medical and industrial use, Nitrogen Gas Plants (PSA MS, DE-OXO, Copper DE-OXO), Biogas Plants, Desiccant & Gas Dryers, and Electrical Panel services. We offer complete installation, servicing, and support for new and existing gas plant systems.

Complete Air & Gas Engineering Solutions

AmsaAir Engineering Pvt. Ltd. is a trusted manufacturer and solution provider for advanced Air & Gas Systems. We specialize in designing, manufacturing, installing, and servicing high-performance gas plants for industrial and medical applications.

From Nitrogen, Oxygen, Hydrogen, Ammonia, and Exo Gas Plants to complete system integration, we deliver reliable and energy-efficient solutions tailored to your process requirements.

Our expertise covers turnkey project execution — from concept and design to commissioning and after-sales support — ensuring seamless performance and long-term reliability.

Your Gas Plant. Fully Controlled. Anytime, Anywhere.

At AmsaAir, we believe in delivering not just equipment, but complete control and confidence. Our systems are built with advanced automation, PLC-based control, and optional remote monitoring, giving you full visibility of your plant operations.

We provide:

✔ Engineering & Custom Design

✔ Installation & Commissioning

✔ AMC / CMC Services

✔ Spare Parts & Upgrades

✔ Pan-India Technical Support

With a strong focus on safety, efficiency, and continuous operation, AmsaAir ensures your gas systems operate smoothly — 24×7.

✅ PSA Nitrogen Gas Generators – High Purity, High Performance

At AmsaAir Engineering Pvt. Ltd., we design advanced PSA Nitrogen Gas Plants with flow rates from 5 to 5000 Nm³/hr and purity from 98% to 99.9999%. Our models include:

- Standard (up to 99.99%)

- High Purity Palladium-DE-OXO (up to 99.9995%)

- Ultra High Purity Copper DE-OXO (up to 99.9999%)

These systems deliver nitrogen at 5 to 400 kg/cm²g pressure and dew points up to (–)80°C, ideal for:

- Fuel tank inerting, furnace blanketing

- Heat treatment, sintering, annealing

- Fire prevention in cement, coal & mining

- Oil tankers, chemical & pharma industries

Built for energy efficiency, low maintenance, and long-term reliability.

✅ PSA & VPSA Oxygen Gas Plants – Reliable, Medical & Industrial Grade

At AmsaAir Engineering Pvt. Ltd., we manufacture robust and efficient PSA & VPSA Oxygen Generation Plants designed for continuous, high-purity oxygen supply from 1 Nm³/hr to 1000 Nm³/hr, with purity up to 95% ±3%.

Available in:

- PSA Models – Ideal for hospitals & industrial use

- VPSA Models – High-efficiency units for large-scale needs

Our plants deliver oxygen at 4 to 200 kg/cm²g, ensuring optimal performance in:

- Medical oxygen supply in hospitals & healthcare centers

- Steel cutting, glass manufacturing & chemical processing

- Oxygen cylinder filling systems for continuous distribution

- Wastewater treatment, furnace enrichment, and ozone generation

Built with low energy consumption, fully automatic control, and zero maintenance hassle — trusted across India for 24/7 reliability.

✅ High-Performance Gas Dryers for Industrial Applications

At AmsaAir Engineering Pvt. Ltd., we manufacture a wide range of Gas Dryers designed to remove moisture from industrial gases like Nitrogen, Hydrogen, Biogas, CO₂, and Natural Gas. Our dryers ensure gas purity, prevent corrosion, and improve equipment life in critical processes.

We offer advanced models including Heatless, Heated, Blower Reactivated, and Molecular Sieve Dryers, custom-built to meet your flow rate and dew point requirements.

Trust AmsaAir for energy-efficient, low-maintenance, and high-reliability gas drying solutions across all major industries.

🌬️ Industrial & Medical-Grade Air Dryers – Reliable Performance by AmsaAir

At AmsaAir Engineering Pvt. Ltd., we offer a complete range of high-performance air dryers designed for industrial, medical, and gas generation applications. Our dryers ensure consistent dry air output with dew points as low as −80°C, making them ideal for PSA Oxygen & Nitrogen Plants, CNC machines, pharmaceuticals, laser cutting, and more.

🔹 Our Air Dryer Solutions Include:

- ✅ Heatless Desiccant Air Dryers – Twin tower design, dew point up to −80°C, ideal for PSA gas plants.

- ✅ Heated Desiccant Air Dryers – Energy-efficient with internal or external heating, low purge loss.

- ✅ Refrigerated Air Dryers – Dew point +2°C to +10°C, suitable for general industrial use.

- ✅ DX-Type Air Dryers (Copper/Palladium) – For ultra-high purity gases (up to 99.999%), with −80°C dew point.

- ✅ Custom-Built Skid/Modular Air Dryers – Compact, pre-wired & pre-piped, tailored for turnkey installations.

All AmsaAir dryers come with automatic moisture drain, digital/PLC controls, and robust build quality for long-term operation with minimal maintenance. Choose AmsaAir for efficient, energy-saving, and reliable air drying systems trusted across industries.

🔥 Ammonia Cracking Unit – High-Purity Hydrogen-Nitrogen Gas Generation

At AmsaAir Engineering Pvt. Ltd., we manufacture efficient and reliable Ammonia Cracking Units for producing a high-purity mixture of Hydrogen (75%) and Nitrogen (25%) gas. These systems use an electrically heated catalyst-filled furnace to crack ammonia (NH₃) into a clean gas mixture, ideal for heat treatment, annealing, sintering, brazing, and bright annealing processes.

✅ Key Features:

- Hydrogen-Nitrogen ratio: 3:1

- Outlet purity: 99.9%

- Operating temperature: 850–950°C

- Skid-mounted with flow meters, safety valves & automation options

- Available with optional drying system for moisture removal

Our ammonia cracker systems are compact, energy-efficient, and maintenance-friendly, making them a preferred choice for metallurgical and furnace applications across industries.

At AmsaAir Engineering Pvt. Ltd., we combine industry-leading expertise with reliable, custom-engineered gas solutions. From PSA Oxygen Plants to advanced Nitrogen systems and biogas technology, we deliver high-quality, energy-efficient, and cost-effective systems backed by expert support. Trusted by top industries across India — choose us for performance, precision, and peace of mind.

🛠️ Industry-Grade Engineering

Custom-built gas plants designed to meet the highest standards in safety, purity, and performance.

⏱️ On-Time Delivery & Installation

We understand deadlines — every project is delivered and installed as promised, without delays.

🧪 Technically Skilled Team

Experienced engineers and technicians with deep expertise in PSA, nitrogen, biogas, and more.

⚡ Efficient & Energy-Saving

Our systems are built to deliver maximum performance with minimum power consumption — reducing operational costs and promoting sustainability for your facility.

🛡️ Long-Term Reliability

Our systems are built to last — with low maintenance, high uptime, and durable components.

💬 Transparent Communication

No hidden costs. No delays. Just honest updates, responsive service, and full client clarity.

📍 Pan-India Support Network

From Greater Noida to any corner of India — we provide fast service, AMC, and on-site support.

🛠️ 20+ Years of Experience

With over four decades in the gas plant industry, we bring unmatched experience and deep technical knowledge to every project — ensuring safe, compliant, and efficient installations.

🤖 Fully Automatic Systems

We offer advanced automation with user-friendly interfaces, remote monitoring, and minimal manual intervention — for total reliability and ease of use.

Clients We Serve

Industries of Expertise

Get a Free Quick Quote

Share your requirements – we’ll get back with a quick estimate.

We’re Just a Call Away

Get an Instant Quote for Gas Plants & Support Services