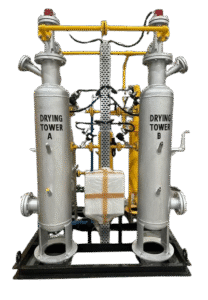

Twin Tower Gas Dryer – Reliable Moisture Removal System for Industrial Use

A Twin Tower Gas Dryer is a highly efficient air treatment system designed to deliver dry, clean, and moisture-free gas or compressed air for industrial and gas plant applications. At AmsaAir Engineering Pvt. Ltd., we manufacture and supply advanced Twin Tower Gas Dryers for PSA Oxygen, Nitrogen, Hydrogen, and Ammonia Cracker units, ensuring peak performance and long equipment life.

What is a Twin Tower Gas Dryer?

A Twin Tower Gas Dryer operates on the adsorption principle, using two parallel towers filled with desiccant material to continuously remove moisture from compressed air or process gas.

While one tower dries the gas, the other regenerates automatically — allowing 24/7 continuous operation without downtime. This system is ideal for industries that require consistent dew point control and high air purity.

Working Principle of Twin Tower Gas Dryer

The operation of the Twin Tower Gas Dryer is based on adsorption and regeneration cycles:

- Adsorption Phase:

Moisture-laden gas enters the drying tower, where the desiccant (such as activated alumina or molecular sieves) adsorbs the moisture. - Regeneration Phase:

The second tower undergoes regeneration using either dry purge air or external heat. Once complete, it switches roles with the first tower.

This alternating twin-tower process ensures uninterrupted drying and maintains a low dew point (up to –80°C or below).

Technical Specifications

| Parameter | Specification |

|---|---|

| Flow Capacity | 5 to 1000 CFM |

| Operating Pressure | 5 – 10 bar |

| Dew Point | Up to –40°C / –80°C |

| Type | Heatless / Heated / Blower Reactivated |

| Design | Skid Mounted / Modular |

| Control | PLC-based Fully Automatic |

| Material | Mild Steel / Stainless Steel Construction |

Types of Twin-Tower Gas Dryers

At AmsaAir Engineering Pvt. Ltd., we offer several models to meet diverse industrial requirements:

1. Heatless Twin Tower Gas Dryer

- Uses a small portion of dried gas for regeneration.

- Economical and suitable for moderate dew point applications.

2. Heated Twin Tower Gas Dryer

- Uses external heaters to regenerate desiccant efficiently.

- Reduced purge loss, ideal for high-capacity systems.

3. Blower Reactivated Gas Dryer

- Uses ambient air through a blower and heater for regeneration.

- Best for continuous high-volume operations with energy savings.

Applications

Twin Tower Gas Dryers are used across multiple industries, including:

- PSA & VPSA Oxygen Gas Plants

- Nitrogen Gas Plants (PSA / DX / CU-DX / Membrane Type)

- Hydrogen Gas Plants & Ammonia Cracker Units

- Pharmaceutical & Food Processing Industries

- Refineries, Power Plants, and Steel Industries

Key Features & Advantages

- Continuous Drying Operation with twin-tower design

- Fully Automatic PLC Control Panel for reliability

- Low Dew Point Output for critical applications

- Energy Efficient with minimum purge air loss

- Durable Construction and easy maintenance

- Compact, Skid-Mounted System for quick installation

Why Choose AmsaAir Engineering Pvt. Ltd.?

- Over a decade of experience in gas generation and air drying technology

- Tailor-made solutions as per process requirements

- 24/7 after-sales service with AMC / CMC support

- Trusted by industries for quality, reliability, and efficiency

Maintenance & After-Sales Support

To ensure optimum performance of your Twin Tower Gas Dryer, AmsaAir Engineering provides:

- Desiccant replacement and system calibration

- Periodic inspection of valves, filters, and sensors

- Preventive Maintenance (AMC / CMC contracts)

- Remote and on-site technical assistance

You may continue reading about PSA oxygen & desiccant air dryer:

Conclusion

A Twin Tower Gas Dryer is the backbone of every industrial gas generation system, providing moisture-free air to maintain purity, protect equipment, and improve process efficiency.

If you’re looking for a reliable, energy-efficient, and high-performance Twin Tower Gas Dryer, contact AmsaAir Engineering Pvt. Ltd. today.

📞 Call: +91-8448199013 / +91-8076023100

📩 Email: info@amsaairengineering.com

Help Us Reach More People!

Help us reach more people! Share this post and help others learn about AmsaAir’s advanced gas plants and services..

Contact Us Instantly

Need help or more information? Reach out to us using any of the options below.