Introduction

At AmsaAir Engineering Pvt. Ltd., we specialize in designing and manufacturing MS, DX, and CU-DX Modules for PSA Nitrogen Gas Plants that deliver exceptional reliability, purity, and performance. Our systems are trusted by industries across India for their ability to generate high-purity nitrogen ranging from 99.5% to 99.9999%, meeting even the most demanding industrial standards.

Whether you need nitrogen for pharmaceuticals, electronics, food packaging, chemical industries, or laser cutting, AmsaAir provides custom-engineered PSA Nitrogen Gas Plants that ensure continuous gas generation with minimal maintenance and maximum energy efficiency.

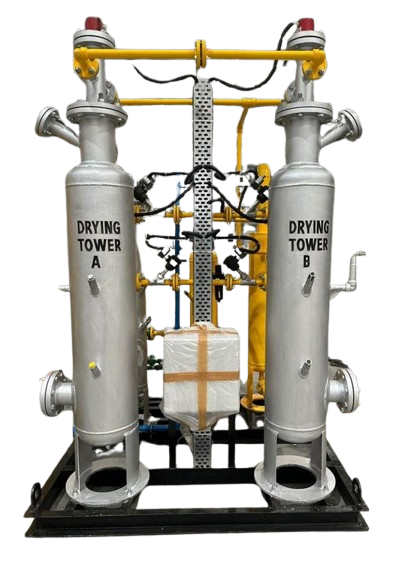

What Are MS, DX, and CU-DX Modules?

1️⃣ MS Model (Molecular Sieve Model):

This is the most widely used PSA nitrogen system, designed for general industrial applications. It uses carbon molecular sieves (CMS) to separate oxygen and nitrogen molecules efficiently. The MS model delivers nitrogen purity between 99.5% and 99.99%, making it ideal for industries like tire manufacturing, heat treatment, and electronics.

2️⃣ DX Model (Dual Purification Model):

The DX model goes one step further by adding an advanced de-oxo purification process, where trace amounts of oxygen are removed using catalytic reactions. This model achieves nitrogen purity up to 99.99%, suitable for food packaging, pharmaceutical, and chemical applications that demand extra cleanliness and reliability.

3️⃣ CU-DX Model (Copper De-Oxo Model):

The CU-DX module uses copper-based catalytic units for enhanced purification. This technology ensures ultra-high purity nitrogen up to 99.9999%, making it perfect for semiconductor manufacturing, stainless steel processing, and precision electronics. Its robust design provides consistent performance, even in continuous operation.

Key Features and Advantages

✅ High Nitrogen Purity:

Each module—MS, DX, and CU-DX—delivers nitrogen purity tailored to your industrial requirement, ranging from 99.5% to 99.9999%.

✅ Energy Efficient:

AmsaAir systems are engineered with advanced control panels and optimized PSA cycle timing, ensuring low power consumption and high output efficiency.

✅ Compact & Modular Design:

The modular structure allows easy installation, expansion, and servicing without production downtime.

✅ Maintenance-Free Operation:

Built with long-lasting molecular sieves, premium valves, and automatic controls, our systems ensure uninterrupted nitrogen generation with minimal maintenance.

✅ Reliable After-Sales Support:

From installation and commissioning to AMC & CMC maintenance, AmsaAir provides complete lifecycle support for every nitrogen gas plant.

Applications of PSA Nitrogen Gas Plants

Our nitrogen generation systems are used across multiple industries:

- Pharmaceutical & Chemical Processing

- Food & Beverage Packaging

- Electronics & Semiconductor Manufacturing

- Laser Cutting & Metal Fabrication

- Heat Treatment & Furnaces

- Tire Inflation & Rubber Processing

Why Choose AmsaAir Engineering?

As a leading Indian manufacturer of PSA & VPSA Gas Plants, Nitrogen Gas Plants, Oxygen Plants, and Air Dryers, AmsaAir Engineering stands for quality, performance, and reliability.

Our MS, DX, and CU-DX PSA Nitrogen Plants are designed in compliance with international standards and customized to suit your specific gas flow, purity, and pressure needs.

We also provide:

- Complete Installation & Commissioning

- Electrical Panel Integration

- 24×7 Customer Support

- Spare Parts Supply & AMC Services

With decades of engineering excellence, we ensure that your gas plant operates at maximum efficiency with minimum downtime.

External Reference

For more technical information about PSA technology and molecular sieve systems, you can refer to Wikipedia’s PSA Nitrogen Gas Plant article.

Help Us Reach More People!

Help us reach more people! Share this post and help others learn about AmsaAir’s advanced gas plants and services..

Contact Us Instantly

Need help or more information? Reach out to us using any of the options below.